compress pressure vessel design calculations

Acting on internal of the pressure. PREPD CHKD REVD APPD PROJECT.

Compress Pressure Vessel Software Overview Youtube

Also calculates the volume and weight.

. COMPRESS also provides a Foundation Loads. Using comercial software you can quickly become a lazy number cruncher that doesnt fully understand the design technique you are using. Chamber MAP cold new is 184851.

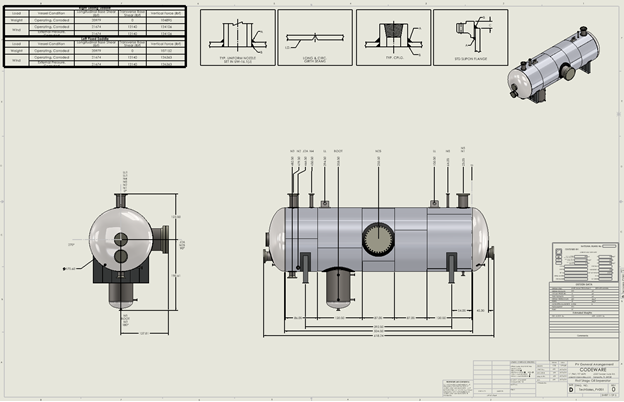

The calculations are done in Compress and the drawing is made in SolidWorks. We use Compress PV Elite Design Calcs Nozzle Pro and our own in-house software. In the first example a nozzle with a reinforcing pad on a cylinder calculation is.

It saves engineering hours while reducing errors and omissions. The design pressure of any pressurised container is the difference between the internal and external pressure. Static head Pressure resulting from weight of liquid.

All pressure vessels subject to an external pressure of 15 psig or greater must meet the requirements of UG-28. There are over 80000 centrifugal chillers. The maximum allowable pressure drop for the upset case was specified to be 138 psig.

With many decades of accumulated pressure vessel engineering and. COMPRESS includes calculations to determine the effect of external loads on pressure vessels as required by ASME paragraph U-2 g. DesignofHeadandShell ShellThicknessUG-27c1 1 Minimumrequiredthickness t PR SE06P estimateE070TblUW12 doubleweldedbuttjoint 52518.

COMPRESS is an expert system that produces professional level pressure vessel design reports with a single button click. Many of the pressure vessel calculations needed to properly design a vessel or exchanger are not by design contained in the ASME VIII BPVC itself. COMPRESS checks your inputs and makes design recommendations.

MECHANICAL DESIGN SOFTWARE COMPRESS OR OTHERS Ch 34 GPTs2 PDF June 11th 2018 - Design Chart 34 A2 Soil Type Adjustment Factors for Trap Area and Sediment Volume Design. PV Elite is software for engineering design and analysis of pressure vessels and heat exchangers also taking into account wind and seismic conditions. NATCO-AL-RUSHAID MIDDLE EAST LTD Jubail Industrial City 31961 COMPRESS Pressure Vessel Design Calculations Item.

Design pressure of vessel includes. Pipe Shell Design Tool Calculate the required wall thickness or the maximum allowed working pressure of an ASME VIII-1 pipe or straight rolled shell. For well over 10 years one particular area of strength has been ASME Section VIII pressure vessel engineering and design.

COMPRESS provides the tools and calculations needed to assist designers with this complex task. Higher liquid height results in higher pressure. Chamber MAWP hot corroded is 1685 kPa 110 C.

This makes it the perfect. See how to use the COMPRESS design mode to optimize two common ASME VIII Code calculations. COMPRESS 2017 Build 7700 ASME.

The design pressure drop through the reactor bed was 100 psig. External pressure design is primarily a function of vessel geometry. Chamber design MDMT is -5 CChamber rated MDMT is -1557 C 1685 kPa.

Vessel Wizard The Vessel Wizard speeds pressure vessel design by creating complete. COMPRESS Pressure Vessel Design Calculations Item. This tower is designed for a combination of seismic wind and external pressure vacuum loads.

At this pressure drop all the. Roarks Formulas for Stress and Strain 7th edition Table 92 Case 1 Pressure Vessel Design Manual. Sample vessel calculations are included throughout this article based on a vessel 48 diameter x 96 long with a Flanged and Dished FD head at one end and a Semi Elliptical.

Division 3 is used for the calculation and design of high pressure equipment around 10000 psig 703 kgcm2g while Div2 and Div1 are used for the rest of applications. To produce a complete set of pressure. If a pressure vessel is exposed to an internal pressure of.

This spreadsheet calculates the a variety of resultant engineering requirments per. Compress is the most user.